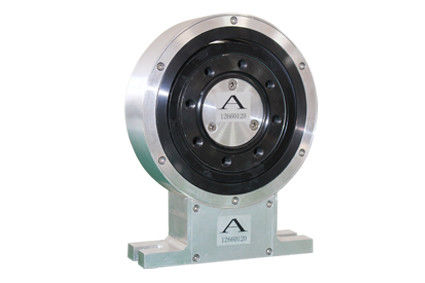

1000Nm 0.1%FS High-precision High Speed Torque Measuring Flange for Rotating Shafts

Torque Sensors

Depending on the application, torques are measured in very different force ranges. SLong offers sensor systems for every application area in production, development and research. We make a distinction between two designs: Torque sensors to measure on rotating shafts Sensors of this type use strain gage technology. They offer maximum accuracy, a very rigid structure and excellent temperature stability. For these torque measuring shafts, transmission of the power supply and the measurement signal is largely contactless. Several features make integration into existing test systems easy: contactless digital signal transmission from the rotor to the stator, integrated signal conditioning, standardized analog and frequency outputs, and numerous interfaces.

Benefits at a Glance

• Torque measurement is integrated in the production process

• Process monitoring ensures zero-defect production

• Quality costs are cut because deviations are detected at an early stage

• Process efficiency is optimized because the measuring equipment used is extremely flexible

Characteristic

- Built in digital measurement signal conditioning unit, through contactless transmission, the data is directly output in standard analog or digital signal mode

- Strong anti-interference ability

- The rotor rotates in the stator ring, no mechanical bearing is allowed, so there is no wear.

- 0.5 or 0.1 precision level, optional current, voltage or frequency signal output

- High precision magnetoelectric angle / speed measuring unit, dust and moisture proof

- Parameter identification, setting, measurement and zero balance of sensor are realized through RS-485 interface

- Very small axial size compact flange flange connection design

- Digital non-contact signal transmission, no bearing, no maintenance, system self-test function

Technical Parameter

- Measuring range: ± 50... 1000 Nm

- Output signal: 5-15kHz/ 0-10V /4-20mA /RS485

- Overload capacity: 120%

- Accuracy class: 0.1%

- Power supply: 24 VDC

- Working speed: 0-12000 rpm

- Response frequency: 100 μ s

- Insulation resistance: > 200m Ω

- Zero drift: < 0.2%

- Repeatability: < 0.1%

- Linearity: < 0.1%

- Lag: < 0.1%

- Ambient temperature: - 40-60 ℃

- Relative humidity: < 90% RH

- Operating temperature range: - 10-70 ℃

- Storage temperature range: - 25-80 ℃

- Sensor amplitude: 10V

- Sensor power consumption: ≈ 4W

- Current consumption of sensor: 100mA

- Response time of dynamic strain wave of strain gauge: 3.2x10-6s

- Sensor housing: strongly anodized aluminum

FAQ

Q:What’s the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q: How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What’s your payment term?

A: Normally 30% T/T deposit, pay in full before shipment.

Q:What’s the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors prodction cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q:Can I come to visit your factory?

A: Sure, you are always welcome to have a visit.

About Us

SeeLong Intelligent Technology (Luoyang Henan) Co., LTD., is a professional production of automotive power system test equipment high technology services enterprises. SeeLong is located in the Peony City(famous for peonies) -- Luoyang, which is also the ancient capital of 13 dynasties.

Why Choose Us

After years of development and accumulation, the company has become a well-known powertrain test equipment production enterprises. Specializing in engine test, transmission test, energy storage test, controls and electric motor test and other test equipment research, development and production service. The company has established long-term cooperation with tsinghua university, Shandong university and many other domestic scientific institutions. We have successfully passed the ISO9001 Quality System certification, obtained a dozen of invention patents and two software copyrights. We have provided professional services and equipment for more than 100 users at home and abroad and which is ongoing now and will continue in the future.

Prospect of Cooperation

Friendly cooperation provides you both high quality products and long-term professional after-sales service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!