400kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench

The 400kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench is a professional testing device tailored for performance evaluation and reliability verification of medium-to-high power transmission components such as gearboxes, reducers, and drive axles. With a rated power of 400KW, it excels in conducting efficiency tests, power performance assessments, comprehensive condition simulations, and long-term durability trials, providing critical technical support for R&D optimization, quality control, and reliability validation in multiple industrial fields.

1. 400kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Core Functions and Design Objectives

The 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench is designed to replicate real-world operating conditions of gearboxes, enabling in-depth analysis of their working performance. Its core functions include:

Accurately measuring transmission efficiency under different speed and load combinations.

Simulating complex working conditions (e.g., start-stop cycles, variable load shocks, and continuous high-load operation) to assess power performance.

Conducting long-term durability tests to verify service life and failure modes.

Monitoring key parameters in real time to support performance optimization and fault diagnosis of gearboxes.

2. Key System Composition and Functional Characteristics

The 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench integrates multiple subsystems, each with dedicated roles to ensure precise, stable, and efficient test processes:

- Input Power & Load System

This dual-function system serves as both a "power source" and a "resistance simulator." On one hand, it provides adjustable power input to the gearbox, mimicking the output characteristics of engines or motors in actual applications; on the other hand, it applies graded loads to simulate road resistance, gradient resistance, and other external forces during vehicle or equipment operation, enabling performance testing under diverse load conditions.

- Output Load & Feedback System

Focused on energy absorption and condition simulation, this system primarily absorbs the power output by the tested gearbox. It also features reverse drive capability, which can simulate special working conditions such as braking, downhill coasting, or reverse operation of equipment, comprehensively evaluating the gearbox’s performance under non-steady-state conditions.

- Energy Recovery & Inversion System

A standout feature of the 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench is its energy-saving design: the system recovers electrical energy generated during load absorption, converts it via a high-efficiency inverter, and feeds it back to the power grid. This energy recycling not only reduces test energy consumption by over 30% but also lowers operational costs, aligning with green testing standards.

- Intelligent Control System

As the "command center" of the test bench, it manages the entire test process through a human-machine interface. Operators can set test parameters (e.g., speed, torque, cycle times, and gear shifts), while the system coordinates the operation of all subsystems using advanced PID closed-loop control algorithms to ensure tests follow preset procedures with minimal deviation.

- Multi-Parameter Acquisition System

Equipped with high-precision sensors and data acquisition modules, this system captures critical operating parameters in real time—including rotational speed, torque, oil temperature, bearing temperature, vibration amplitude, and oil pressure—at a sampling frequency of up to 1kHz. The collected data is instantly stored and preprocessed, laying the foundation for subsequent performance analysis.

- Mechanical Support Structure

The robust mechanical framework, consisting of a vibration-isolated base, adjustable brackets, and high-precision coupling shafts, ensures stable installation of the tested gearbox and auxiliary equipment. Its design minimizes vibration transmission and positional deviations, reducing interference with test accuracy caused by mechanical resonance.

- Lubrication & Cooling Management System

This system provides continuous lubrication for the gearbox by delivering clean, temperature-controlled lubricating oil. It precisely regulates oil temperature (ranging from 40°C to 80°C) and oil pressure, ensuring the gearbox operates under optimal lubrication conditions. Additionally, it monitors oil contamination levels and particle counts to assess wear status during long-term tests.

- Intelligent Monitoring & Safety Protection System

Integrating high-definition cameras and acoustic sensors, this system monitors the test bench’s operating status in real time, capturing abnormal phenomena such as oil leakage, abnormal noise, or component deformation. It is linked to the control system to trigger automatic shutdowns or alarm prompts when dangerous conditions (e.g., excessive temperature or torque) are detected, ensuring test safety.

3. 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench Working Principle and Test Process

The 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench follows a systematic workflow to ensure reliable and repeatable test results:

Pre-Test Setup

Operators define test objectives (e.g., efficiency test or durability test) and set key parameters (speed range, torque load, test duration, and cycle modes) through a user-friendly touchscreen interface. The control system then verifies equipment status (e.g., lubrication pressure, sensor calibration, and power supply stability) to confirm readiness.

Test Execution

The input power system drives the gearbox to operate according to preset speed and torque curves, simulating power input from engines or motors.

The output load system applies dynamic or static loads to the gearbox’s output end, replicating resistance from vehicle wheels, industrial machinery, or other driven components.

The control system adjusts input power and output load in real time based on feedback from the acquisition system, maintaining stable test conditions within a deviation range of ≤±2%.

Data Collection & Monitoring

During operation, the acquisition system continuously records parameters, while the monitoring system tracks equipment status. Key data and video footage are synchronized and stored in a centralized database for traceability.

Post-Test Analysis

After the test, dedicated software analyzes the collected data to calculate core indicators such as average transmission efficiency, peak torque capacity, vibration frequency spectrum, and temperature rise curves. A detailed test report is automatically generated, including data comparisons with industry standards or design requirements, to support performance evaluation and optimization suggestions.

4. 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench Environmental Requirements and Operational Conditions

To ensure test accuracy and equipment longevity, the SSCD400 test bench requires specific environmental and operational conditions:

Power Supply Specifications

AC power supply: Three-phase 380V±5%, single-phase 220V±5%, frequency 50Hz±0.5Hz.

Supporting equipment: A three-phase isolation transformer to reduce grid interference, and an active power filter to limit harmonic distortion to <3%. An online UPS with 20 minutes of backup power ensures data integrity during unexpected power outages.

Environmental Parameters

Installation location: A dedicated laboratory with constant temperature and humidity control, with ambient temperature ranging from -5°C to 40°C and relative humidity ≤80% (non-condensing).

Vibration control: The laboratory floor must be vibration-isolated, with peak vibration acceleration ≤3m/s² to avoid interference with precision measurements.

Cooling requirements: Equipped with a forced-air cooling system with a cooling capacity of no less than 15kW, supplemented by ventilation ducts to dissipate heat generated by the dynamometers and gearbox.

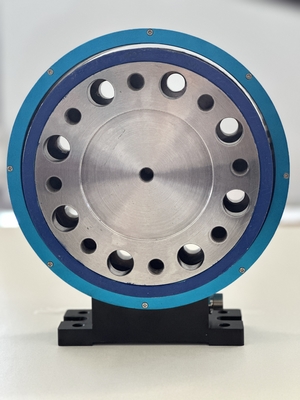

5. 400kW Electric Dynamometer Technical Parameters

| Parameter Item |

Input Dynamometer (SSCD400-1500/3500) |

Output Dynamometer (SSCD400-300/700) |

| Rated power |

400KW |

400KW |

| Rated speed |

1500 rpm |

300 rpm |

| Constant torque speed range |

0-1500 rpm |

0-300 rpm |

| Constant power speed range |

1500-3500 rpm |

300-700 rpm |

| Maximum speed |

3500 rpm |

700 rpm |

| Rated torque |

2547 Nm |

12733 Nm |

| Overload capacity |

125% |

125% |

| Rated voltage |

AC 380V |

AC 380V |

| Cooling method |

Forced air cooling |

Forced air cooling |

| Encoder model |

Shanghai Jingfen HTL 512 |

Shanghai Jingfen HTL 512 |

| Safety monitoring sensors |

Bearing temperature sensors (×2), coil temperature sensors (×3), vibration sensors (×2) |

Bearing temperature sensors (×2), coil temperature sensors (×3), vibration sensors (×2) |

6. 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench Application Fields

The 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench is widely applied in industries requiring reliable medium-power transmission systems:

Commercial Vehicle Sector: Testing transmission gearboxes for trucks and buses to verify performance under heavy loads and long-distance operation.

Engineering Machinery: Evaluating reducers for excavators, loaders, and cranes to ensure durability under variable load conditions.

Agricultural Machinery: Validating gearboxes for tractors and harvesters to adapt to complex field working environments.

Marine Auxiliary Equipment: Assessing gearboxes for ship pumps, winches, and other auxiliary systems to meet marine operational standards.

7. 400kW Gearbox and Axle Performance Testing and Reliability Testing Bench Reference Standards

The test procedures and evaluation criteria of the SSCD400 test bench comply with industry standards such as:

QC/T 568-2019 Technical Requirements and Bench Test Methods for Automotive Mechanical Transmission Assemblies

GB/T 14235.1-2021 General Specifications for Gearbox Test Benches

In summary, the SSCD400 Gearbox Performance Test Bench combines precision, efficiency, and safety, making it an indispensable tool for upgrading transmission technology in medium-power industrial fields.

Company Profile

Seelong Intelligent Technology (Luoyang) Co., Ltd. is a high-tech enterprise specializing in equipment measurement, control, design, manufacturing, and sales services for power engineering systems in various fields such as aerospace, automotive, and new energy; The company is located in the beautiful peony city of Luoyang.

Seelong specializes in the research and development, production, and service of testing equipment for new energy motors, hybrid power systems, engines, transmissions, and more. Our main products include electric dynamometers, measurement and control systems, DC power supplies, and working condition guarantee systems. Seelong has a complete sales and service system, adhering to the business philosophy of providing fine quality services for survival and keeping on renovation for development, and providing users with various types of power engineering measurement and control solutions in various fields.

Seelong's advanced design philosophy and rich industry experience give the company a technological Advantages ahead of competitors in the same industry, and the company's products can better meet the actual market demand. Seelong is brave in innovation. While valuing its own technological breakthroughs and development, it has established long-term and in-depth cooperative relationships with multiple domestic research institutions such as Tsinghua University and Shandong University. It has passed CE certification, ISO9001 quality system certification, AAA level enterprise certification, obtained more than ten invention patents, and two software copyrights. It has provided professional equipment and services to more than a hundred users both domestically and internationally, The enterprise has won the trust of domestic and foreign customers with its cost-effective products and high-quality services, and has established a long-term win-win strategic partnership.

The company always adheres to the business philosophy of "taking technological innovation as its mission and quality service as its purpose", constantly surpassing the advanced level in the same industry, integrating into the world, measuring and controlling the future, and creating high-quality products. To provide customers with products and services with high intelligence, precision, speed, reliability, and added value.

All employees of Seelong Intelligent Technology (Luoyang) Co., Ltd. warmly welcome sincere cooperation from domestic and foreign customers, and work together for the future and common development.

Company Certificates

Packaging and Shipping

FAQ

Q: What's the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q:How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What's your payment term?

A: Normally 40% T/T deposit, pay in full before shipment.

Q:What's the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors production cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q: Can I come to visit your factory?

A: Sure, you are always welcomed to have a visit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!