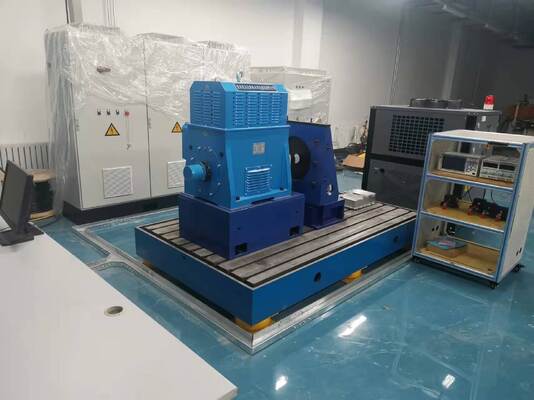

3. SSCD450-1500/3800 450KW New Energy Vehicle Motor Dynamometer Test Bench System Core Technical Advantages

1) High power and precise matching: 450kW rated power, 2865Nm peak torque, and 3800rpm maximum speed, perfectly covering the full-condition testing requirements of drive motors for new energy commercial vehicles and heavy-duty passenger vehicles. The constant power range runs through the entire high-speed operation range, matching the actual working characteristics of the motor.

2) Ultra-high measurement accuracy: It adopts the HBM T40FM high-precision torque sensor (0.15% FS) and Seelong WT6000 power analyzer (0.02% basic accuracy), and is equipped with a 1000Hz high-speed data acquisition system to ensure accurate capture of key parameters such as torque, power, temperature, and vibration, with data errors far below industry standards.

3) Full-scenario compatibility: The battery simulator supports 8 mainstream and new battery models, 30-1500V wide voltage output, 1200A peak current, and is compatible with motors of different voltage levels; the ABB frequency conversion system is compatible with 380V±15% wide voltage input, adapts to different power grid environments around the world, and has stronger stability.

4) Flexible customization and high stability: The system integrates core functions such as measurement and control, analysis, and data storage. Customized brackets, couplings, and other components can be selected. The bracket has an adjustment range of 250-600mm to accommodate various motor models. The combination of HT350 cast iron plate and composite damping shock absorber effectively suppresses vibrations during high-speed operation, ensuring the stability of test data.

5) Intelligent and efficient operation: The XLP-2000 measurement and control software supports custom test process editing, real-time data visualization, and automatic report generation. Combined with remote debugging function, it greatly improves testing efficiency; the bilingual Chinese and English operation interface is adapted to the needs of international users.

4. SSCD450-1500/3800 450KW New Energy Vehicle Motor Dynamometer Test Bench System Application Areas

1) New energy vehicles field: we focus on the performance testing of drive motors for new energy commercial vehicles (buses, logistics vehicles, heavy trucks) and high-end passenger vehicles, covering power verification, torque characteristics, efficiency analysis, durability testing, dynamic response testing, etc., to meet the supporting needs of ternary lithium, lithium iron phosphate, and solid-state batteries.

2) Motor manufacturing industry: Providing factory testing, type testing, and reliability verification for new energy drive motors of 450kW and below to motor manufacturers, helping to control product quality and optimize performance.

3) Research and testing institutions: Provide high-power motor research and testing platforms for universities, research institutes, and third-party testing laboratories, support customized testing solutions, and meet the needs of new technology research and development, standard compliance certification, etc.

4) Special vehicles field: adaptable to special testing of auxiliary drive motors for new energy construction machinery, new energy ships, and rail transit, capable of withstanding high loads and long-term continuous operation, and meeting the stringent testing requirements of special scenarios.

5. SSCD450-1500/3800 450KW New Energy Vehicle Motor Dynamometer Test Bench System Reference Standards

National Standards

- GB/T 18488.1-2015 "Drive motor system for electric vehicles - Part 1: Specification",

- GB/T 18488.2-2015 "Drive motor system for electric vehicles - Part 2: Test Methods",

- GB/T 755-2019 "Rotating Electrical Machines - Rating and Performance",

- GB/T 29307-2022 "Reliability test methods of drive motor system for electric vehicles".

International Standards

- ISO 15084-1:2017 Road vehicles - Electric drive systems - Part 1: Power interfaces,

- IEC 60034-1:2017 Rotating electrical machines - Part 1: Ratings and performance,

- ISO 6469-5:2022 Electric vehicles - Safety requirements - Part 5: Power systems.

Component-specific Standards

- HBM T40FM torque sensor complies with the ISO 16613:2013 calibration standard,

- Siemens variable frequency inverter system complies with the IEC 61800-5-1 safety standard and the IEC 61800-2 adjustable speed electric drive system standard,

- Power analyzer complies with the IEC 62053-22 accuracy standard.

6. New Energy Vehicle Motor Electric Dynamometer Test Bench System Model List

| Model |

Power (KW) |

Torque (Nm) |

Rated Speed (rpm) |

Max Speed (rpm) |

Torque Measurement Accuracy |

| SSCD15-1000/4500 |

15 |

143 |

1000 |

4000 |

0.15%FS |

| SSCD30-1000/4500 |

30 |

286 |

1000 |

4000 |

0.15%FS |

| SSCD45-1000/4000 |

45 |

430 |

1000 |

4000 |

0.15%FS |

| SSCD60-1000/4000 |

60 |

573 |

1000 |

4000 |

0.15%FS |

| SSCD75-1000/4000 |

75 |

716 |

1000 |

4000 |

0.15%FS |

| SSCD90-1000/3500 |

90 |

859 |

1000 |

3500 |

0.15%FS |

| SSCD110-1000/3500 |

110 |

1050 |

1000 |

3500 |

0.15%FS |

| SSCD160-1000/3500 |

160 |

1528 |

1000 |

3500 |

0.15%FS |

| SSCD200-1000/3300 |

200 |

1910 |

1000 |

3300 |

0.15%FS |

| SSCD250-1000/3300 |

250 |

2387 |

1000 |

3300 |

0.15%FS |

| SSCD300-1000/3300 |

300 |

2865 |

1000 |

3300 |

0.15%FS |

| SSCD30-1500/5000 |

30 |

191 |

1500 |

5000 |

0.15%FS |

| SSCD45-1500/5000 |

45 |

286 |

1500 |

5000 |

0.15%FS |

| SSCD60-1500/5000 |

60 |

382 |

1500 |

5000 |

0.15%FS |

| SSCD90-1500/5000 |

90 |

573 |

1500 |

5000 |

0.15%FS |

| SSCD132-1500/4500 |

132 |

840 |

1500 |

4500 |

0.15%FS |

| SSCD160-1500/4500 |

160 |

1019 |

1500 |

4500 |

0.15%FS |

| SSCD200-1500/4000 |

200 |

1273 |

1500 |

4000 |

0.15%FS |

| SSCD250-1500/4000 |

250 |

1592 |

1500 |

4000 |

0.15%FS |

| SSCD300-1500/3800 |

300 |

1910 |

1500 |

3800 |

0.15%FS |

| SSCD315-1500/3800 |

315 |

2005 |

1500 |

3800 |

0.15%FS |

| SSCD350-1500/3800 |

350 |

2228 |

1500 |

3800 |

0.15%FS |

| SSCD400-1500/3800 |

400 |

2546 |

1500 |

3800 |

0.15%FS |

| SSCD450-1500/3800 |

450 |

2865 |

1500 |

3800 |

0.15%FS |

| SSCD500-1500/3800 |

500 |

3183 |

1500 |

3800 |

0.15%FS |

7. Delivery and After-sales Support

Delivery

Standard models ship within 90 days, while customized models ship within 120-150 days (including international logistics and customs clearance assistance). Delivery includes a complete set of equipment, installation instructions, operation manual, calibration certificate, spare parts list, and other complete documentation. On-site installation and commissioning are supported.

After-sales service

1) Warranty service: Core components (dynamometer, torque flange, variable frequency inverter system) are guaranteed for 1 year, and faulty parts will be repaired or replaced free of charge during the warranty period.

2) Technical support: Lifetime bilingual (Chinese and English) technical support is provided, with a response time less than or equal to 4 hours; remote debugging (computer-based), modular solution configuration guidance, and online answers to technical questions are supported.

3) Training services: We provide 2 days of free on-site operation training, covering equipment installation, parameter settings, operating condition testing, data analysis, and daily maintenance, to ensure that users are proficient in operating the system.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!