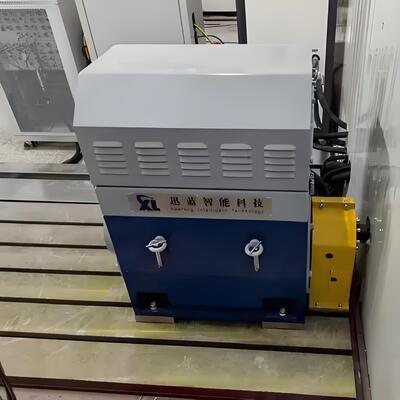

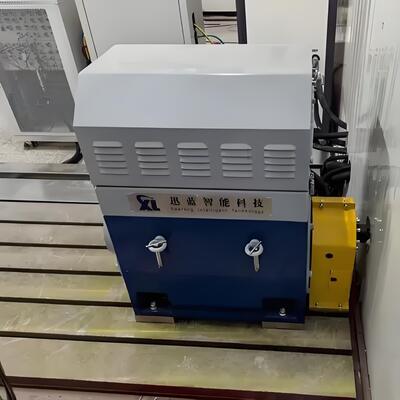

SSCD315-1500/3800 315KW New Energy Vehicle Motor Electric Dynamometer Test Bench System

1. SSCD315-1500/3800 315KW New Energy Vehicle Motor Electric Dynamometer Test Bench System Component Description

The SSCD315-1500/3800 315kW Motor Electric Dynamometer Test Bench System is a high-end comprehensive testing platform developed for 315kW high-power motors in medium and heavy-duty commercial vehicles, engineering equipment, and other fields. The system integrates a electric dynamometer, high-precision sensing units, an intelligent measurement and control center, and a wide-area energy simulation system. It can realize full-condition performance verification, durability testing, and fault simulation analysis of motors, and is suitable for the testing needs of mid-range high-power motors in new energy medium and heavy-duty trucks, medium-sized engineering machinery, and special vehicle propulsion systems.

| Component Name |

Core Specifications |

Brand |

| SSCD315-1500/3800 Electric Dynamometer |

Power: 315KW; Rated speed: 1500rpm; Rated torque: 2001Nm; Maximum speed: 3800rpm; Constant power speed: 1500-3800rpm; High-efficiency water-cooling system. |

Seelong |

| High-precision torque sensor |

Measuring range: 0-3000Nm (accuracy: 0.15% FS), dynamic response time ≤1ms |

HBM |

| Intelligent variable frequency inverter system |

Input voltage: three-phase AC 380V-480V; frequency: 50-60Hz; overcurrent protection value: 1.8 times rated current; equipped with vector control technology, supporting precise torque adjustment, and integrating surge protection, short circuit protection, and temperature warning triple protection mechanism. |

Siemens |

| XLP-1000 measurement and control system |

Industrial PC: IPC710, CPU: i7, Memory: 32GB, Hard Disk: 1TB , XLP-1000 Measurement and Control System Software |

Seelong |

| Data acquisition system |

Includes temperature/vibration/noise/pressure acquisition units; temperature range -40~300℃ (accuracy ±0.3℃); vibration frequency 5Hz-20kHz; pressure measurement range 0-10MPa (accuracy ±0.2% FS). |

Seelong |

| Power analyzer |

Model: WT3006; Basic Accuracy: 0.03% (0.01% of reading + 0.02% of range); Bandwidth: DC, 0.1Hz -1MHz; LCD Touchscreen > 6 Channels + MTR |

Seelong |

| Current transformer |

Measuring range 1000A, accuracy class 0.03% FS, insulation class F. |

Seelong |

| Battery simulator |

Output voltage: 36-1200V; Rated power: 315kW; Peak power: 400kW; Rated current: 800A; Peak current: 1000A; Feedback voltage: 380-450V; Supports 8 types of battery models (including solid-state battery simulation). |

Seelong |

| Optional components |

High-performance couplings |

Permissible speed: 6000 rpm, permissible torque: 3000 Nm, elastic buffer structure |

| |

Adjustable motor bracket |

Bracket adjustment range (motor center height): 250mm-600mm; load capacity: ≥400kg |

| |

High-precision cast iron platform |

Material: HT350 (tensile strength ≥350MPa), honeycomb damping structure, flatness error ≤0.02mm/m |

| |

Composite shock absorber |

Adjustable damping spring shock absorber with a damping efficiency of ≥92%, suitable for vibration suppression requirements in medium to high power testing. |

2. SSCD315-1500/3800 315KW Electric Dynamometer Technical Parameters

| Parameters |

Technical indicators |

| Electric dynamometer manufacturer |

Seelong |

| Rated power |

315kW |

| Rated torque |

2001Nm |

| Rated speed |

1500rpm |

| Maximum speed |

3800rpm |

| Constant torque speed range |

0-1500rpm |

| Constant power speed range |

1500-3800rpm |

| Torque sensor model |

T40FM |

| Torque sensor manufacturer |

HBM |

| Torque sensor range (Nm) |

0-3000Nm |

| Accuracy level |

0.15%FS |

3. SSCD315-1500/3800 315KW New Energy Vehicle Motor Dynamometer Test Bench System Core Advantages

1) High power with precise adaptation: The core dynamometer has a rated power of 315KW, a torque range of 0-3000Nm, a maximum speed of 3800rpm, and a constant power range of 1500-3800rpm. It is precisely matched to the full load and extreme working condition testing requirements of mid-range high power motors in medium and heavy-duty commercial vehicles and medium-sized construction machinery. It is compatible with motor products with multiple speed characteristics, making the adaptability more targeted.

2) Industry-leading measurement accuracy: Equipped with an HBM high-precision torque sensor (accuracy 0.15% FS) and a Seelong WT3006 power analyzer (basic accuracy 0.03%), along with a 10kHz high-speed data acquisition module, it achieves accurate capture of key parameters such as torque, power, temperature, and vibration, with a data error rate of less than 0.3%, meeting high-precision testing standards.

3) The system offers flexible scalability: the battery simulator supports a wide voltage output of 36-1200V and 8 types of battery models (including emerging solid-state batteries), with a peak current of 1000A, adaptable to various mid-range high-power motor power supply systems; the Siemens intelligent variable frequency inverter system is compatible with a wide voltage input of 380V-480V, and achieves dynamic response and rapid adjustment based on vector control technology, exhibiting excellent operational stability and anti-interference capabilities, and its functional modules can be expanded according to testing requirements.

4) Reliable and durable structural design: All core components have undergone long-term verification under medium and high power conditions. Optional high-load-bearing mounting brackets (250-600mm adjustable), HT350 high-strength cast iron platforms, and composite shock absorbers can be equipped to effectively suppress vibration interference during testing and ensure long-term stable operation of the equipment. The modular design supports functional expansion and customized modification, making maintenance more convenient.

4. SSCD315-1500/3800 315KW New Energy Vehicle Motor Electric Dynamometer Test Bench System Application Areas

1) Medium and heavy-duty new energy vehicles field: adaptable to power, torque, efficiency, durability and high and low temperature environment adaptability testing of drive motors for new energy medium and heavy-duty trucks, medium-sized buses, light mining vehicles, etc., and matching the mainstream power battery matching requirements.

2) Medium-sized industrial equipment field: We can conduct factory testing, type testing and reliability verification for industrial drive motors of 315KW and below, small and medium-sized generator sets and compressor matching motors, covering application scenarios in light industry, building materials, general machinery and other industries.

3) Mid-range special equipment sector: it meets the special testing needs of special motors for small and medium-sized engineering machinery (loaders, mini excavators), special vehicle propulsion systems, light rail transit traction motors, etc., and is adapted to complex working conditions with medium to high torque, wide speed, and medium impact.

4) R&D and testing sector: We provide local research institutes, automotive R&D centers, and third-party testing organizations with performance R&D, standard compliance testing, and customized testing solutions for mid-range high-power motors, supporting the optimization and innovative verification of mature motor technologies.

5. SSCD315-1500/3800 315KW New Energy Vehicle Motor Electric Dynamometer Test Bench System Reference Standards

National Standards

- GB/T 18488.1-2015 "Drive motor system for electric vehicles - Part 1: Specification",

- GB/T 18488.2-2015 "Drive motor system for electric vehicles - Part 2: Test Methods",

- GB/T 755-2019 "Rotating Electrical Machines - Rating and Performance",

- GB/T 29307-2022 "Reliability test methods of drive motor system for electric vehicles".

International Standards

- ISO 15084-1:2017 Road vehicles - Electric drive systems - Part 1: Power interfaces,

- IEC 60034-1:2017 Rotating electrical machines - Part 1: Ratings and performance,

- ISO 6469-5:2022 Electric vehicles - Safety requirements - Part 5: Power systems.

Component-specific Standards

- HBM T40FM torque sensor complies with the ISO 16613:2013 calibration standard,

- Siemens variable frequency inverter system complies with the IEC 61800-5-1 safety standard and the IEC 61800-2 adjustable speed electric drive system standard,

- Power analyzer complies with the IEC 62053-22 accuracy standard.

6. New Energy Vehicle Motor Electric Dynamometer Test Bench System Model List

| Model |

Power (KW) |

Torque (Nm) |

Rated Speed (rpm) |

Max Speed (rpm) |

Torque Measurement Accuracy |

| SSCD15-1000/4500 |

15 |

143 |

1000 |

4000 |

0.15%FS |

| SSCD30-1000/4500 |

30 |

286 |

1000 |

4000 |

0.15%FS |

| SSCD45-1000/4000 |

45 |

430 |

1000 |

4000 |

0.15%FS |

| SSCD60-1000/4000 |

60 |

573 |

1000 |

4000 |

0.15%FS |

| SSCD75-1000/4000 |

75 |

716 |

1000 |

4000 |

0.15%FS |

| SSCD90-1000/3500 |

90 |

859 |

1000 |

3500 |

0.15%FS |

| SSCD110-1000/3500 |

110 |

1050 |

1000 |

3500 |

0.15%FS |

| SSCD160-1000/3500 |

160 |

1528 |

1000 |

3500 |

0.15%FS |

| SSCD200-1000/3300 |

200 |

1910 |

1000 |

3300 |

0.15%FS |

| SSCD250-1000/3300 |

250 |

2387 |

1000 |

3300 |

0.15%FS |

| SSCD300-1000/3300 |

300 |

2865 |

1000 |

3300 |

0.15%FS |

| SSCD30-1500/5000 |

30 |

191 |

1500 |

5000 |

0.15%FS |

| SSCD45-1500/5000 |

45 |

286 |

1500 |

5000 |

0.15%FS |

| SSCD60-1500/5000 |

60 |

382 |

1500 |

5000 |

0.15%FS |

| SSCD90-1500/5000 |

90 |

573 |

1500 |

5000 |

0.15%FS |

| SSCD132-1500/4500 |

132 |

840 |

1500 |

4500 |

0.15%FS |

| SSCD160-1500/4500 |

160 |

1019 |

1500 |

4500 |

0.15%FS |

| SSCD200-1500/4000 |

200 |

1273 |

1500 |

4000 |

0.15%FS |

| SSCD250-1500/4000 |

250 |

1592 |

1500 |

4000 |

0.15%FS |

| SSCD300-1500/3800 |

300 |

1910 |

1500 |

3800 |

0.15%FS |

| SSCD315-1500/3800 |

315 |

2005 |

1500 |

3800 |

0.15%FS |

| SSCD350-1500/3800 |

350 |

2228 |

1500 |

3800 |

0.15%FS |

| SSCD400-1500/3800 |

400 |

2546 |

1500 |

3800 |

0.15%FS |

| SSCD450-1500/3800 |

450 |

2865 |

1500 |

3800 |

0.15%FS |

| SSCD500-1500/3800 |

500 |

3183 |

1500 |

3800 |

0.15%FS |

7. Delivery and After-sales Support

Delivery

Standard models ship within 90 days, while customized models ship within 120-150 days (including international logistics and customs clearance assistance). Delivery includes a complete set of equipment, installation instructions, operation manual, calibration certificate, spare parts list, and other complete documentation. On-site installation and commissioning are supported.

After-sales service

1) Warranty service: Core components (dynamometer, torque flange, variable frequency inverter system) are guaranteed for 1 year, and faulty parts will be repaired or replaced free of charge during the warranty period.

2) Technical support: Lifetime bilingual (Chinese and English) technical support is provided, with a response time less than or equal to 4 hours; remote debugging (computer-based), modular solution configuration guidance, and online answers to technical questions are supported.

3) Training services: We provide 2 days of free on-site operation training, covering equipment installation, parameter settings, operating condition testing, data analysis, and daily maintenance, to ensure that users are proficient in operating the system.

8. FAQ

Q: What's the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q:How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What's your payment term?

A: Normally 40% T/T deposit, pay in full before shipment.

Q:What's the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors production cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q: Can I come to visit your factory?

A: Sure, you are always welcomed to have a visit.

9. Our Certificates

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!