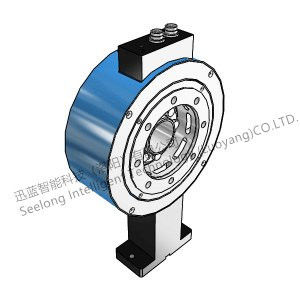

SLFN-2000Nm 0-8000rpm 0.2%FS economical torque flange for dynamometer

Torque sensors

The SLFN flange sensor is ideal for test bench applications such as engine, dynamometer and electric motor test bench applications, wheel load simulation test bench applications, gearbox and pump test bench applications.

The flange torque sensor with high rigidity and high speed response developed for the purpose of detecting the variable torque of engine or drive system.TQ-2000 series of sensors have high torsion rigidity, and can measure rapidly changing torque more accurately than the original torque sensors of our company.Because it is a thin flange structure without bearings, it can be directly installed on the rotating shaft, and the entire installation space is small.

Product features

- Compared with the original products of our company, the rigidity is about 20 times higher and the responsiveness is much faster

- ± 0.05% /F.S (frequency output)

- The signal transmission from the rotating part is non-contact, so it is easy to set up and maintain

- The maximum speed of TQ-2000 series is up to 25,000 r/min (optional function). The standard is 22,000 r/min

- Space saving thin flange

- Can perform JISS calibration (JISS: Japanese calibration service system, corresponding to international mutual recognition MRA)

Technical parameter

|

Measuring range

|

0±50N.m ±100N.m ±200N.m ±500N.m ±1000N.m

±2000N.m ±5000N.m ±1 万 N.m

|

|

Output signal

|

5-15KHZ 0-10V 4-20mA

|

Overload capacity

|

120%

|

|

Accuracy

|

0.5% 0.2%

|

Power supply

|

24VDC

|

|

Optimum operating Speed

|

0-15000 rpm

|

Response frequency

|

500μs

|

|

Insulation resistance

|

>200MΩ

|

Zero drift

|

<0.5%

|

|

Repetitive

|

<0.1%

|

Linear

|

<0.1%

|

|

Lag

|

<0.1%

|

Environment temperature

|

-40-60℃

|

|

Relative humidity

|

<90%RH

|

Temperature range

|

-10-70℃

|

|

Amplitude of transmitter

|

10V

|

Storage temperature range

|

-25-80℃

|

|

Transducer power consumption

|

≈4W

|

Sensor current consumption

|

100MA

|

|

Sensor shell

|

Strong anodized aluminum

|

The response time of the strain gauge dynamic strain wave

|

3.2X10-6s

|

fundamental principles

1. Measurement of torque:The electric signal of torsion of the elastic shaft can be measured by lifting the power supply to the elastic shaft, and the strain bridge is formed on the elastic shaft by the strain gauge electric measurement technology. The strain signal is amplified and converted into a frequency signal proportional to the torsion after voltage frequency conversion.

2. Measurement of rotational speed:Corresponding gear speed using photoelectric switch speed encoder measurement, each circle is 60 teeth gear speed encoder (120 teeth) are optional, every revolving gear encoder can produce 60 pulse, when the continuous rotation speed encoder, through the photoelectric switch output pulse signal, according to the number of teeth on the encoder and the output signal, can calculate the corresponding rotational speed.

3. Wiring Method

1.negative power supply

2.positive power supply

4.speed signal

5.torque signal

4.Output signal and signal acquisition

1.Torque signal output basic form of square wave signal, pulse signal. Voltage analog signal output or current analog signal output can be made according to user needs.

2. Torque signal processing form

(1) The output frequency signal of the torque sensor is sent to the frequency meter or digital meter, and the frequency signal or voltage and current signal which is directly proportional to the torque is read.

(2) The torque and frequency signals of the torque sensor are sent to the DSP secondary instrument, which directly displays the real-time torque value, speed and output power value as well as RS232 and 485 communication signals.

5.Installation and use

1. Use environment: the torque sensor should be installed in the environment where the ambient temperature is 0℃ ~ 60℃, the relative humidity is less than 90%, and there are no flammable or explosive products. Should not be installed in the environment of strong electromagnetic interference.

2. Connection mode:Using two couplings, the belt torque sensor is mounted between the power source and the load. Power and load equipment must be fixed and reliable to avoid vibration.

3. installation requirements

(1) The sensor can be installed horizontally or vertically, and can be connected with a flexible coupling or a rigid coupling.

(2) Power equipment, sensors and load equipment should be installed on a solid foundation to avoid excessive vibration, otherwise data signal instability may occur, reduce the measurement accuracy, or even damage the sensor.

(3) The concentricity of power devices, sensors, load axis should be less than 0.05 mm Φ.

FAQ

Q:What’s the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q: How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What’s your payment term?

A: Normally 30% T/T deposit, pay in full before shipment.

Q:What’s the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors prodction cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q:Can I come to visit your factory?

A: Sure, you are always welcome to have a visit.

About Us

SeeLong Intelligent Technology (Luoyang Henan) Co., LTD., is a professional production of automotive power system test equipment high technology services enterprises. SeeLong is located in the Peony City(famous for peonies) -- Luoyang, which is also the ancient capital of 13 dynasties.

Why Choose Us

After years of development and accumulation, the company has become a well-known powertrain test equipment production enterprises. Specializing in engine test, transmission test, energy storage test, controls and electric motor test and other test equipment research, development and production service. The company has established long-term cooperation with tsinghua university, Shandong university and many other domestic scientific institutions. We have successfully passed the ISO9001 Quality System certification, obtained a dozen of invention patents and two software copyrights. We have provided professional services and equipment for more than 100 users at home and abroad and which is ongoing now and will continue in the future.

Prospect of cooperation

Friendly cooperation provides you both high quality products and long-term professional after-sales service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!