600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench

The gearbox performance test bench is mainly used to complete the performance test and reliability test of the transmission, drive axle, etc., and can meet the test requirements of the test piece such as efficiency test, dynamic test, performance test, reliability test, etc. The gearbox durability test bench is mainly composed of the input end dynamometer system (drive and load), the output end dynamometer system (load and drive), the feedback variable frequency inverter system, the control system, the data acquisition system, the bench mechanical system, the oil station system, the video monitoring system, etc.

1. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Components

The electric dynamometer is used as a loading/dragging device for the motor to load/drag the transmission; the electric dynamometer is mainly composed of an AC motor host, a torque flange, an electric dynamometer mounting base, etc. The motor of the electric dynamometer uses SSCD series high-torque products; a torque measuring device is installed on the electric dynamometer for torque measurement; at the same time, an encoder is installed on the electric dynamometer for speed measurement.

- Variable frequency inverter system:

The DTC series frequency conversion control system is used to control the electric dynamometer; the system operates in four quadrants to control the electric dynamometer for loading. The electric energy generated after loading is fed back to the DC bus through the variable frequency inverter system to drive the electric dynamometer.

- XLP2000 control system and control software:

Our company's XLP2000 numerical control system is used for the overall control of the test bench; the XLP2000 control system communicates with the variable frequency inverter system through the bus to complete the setting and control of each working condition of the test bench; the XLP2000 control system receives various parameters collected by the system through the CAN bus, and at the same time the XLP2000 control system integrates external auxiliary equipment, centralizes communication and control; the entire test process can be completed automatically.

Equipped with corresponding temperature sensors and temperature acquisition modules, it is used to collect parameters such as the temperature of each part and the temperature of the lubricating oil, and upload the collected data to the XLP2000 control system through the bus to realize data display, recording and processing.

- Coupling and protective cover:

A universal joint transmission shaft is used to connect the transmission shaft system; a protective cover is installed on the upper part of the rotating parts such as the coupling for protection. The coupling is connected to the tested transmission through the tooling to complete the connection of the transmission system of the entire test bench.

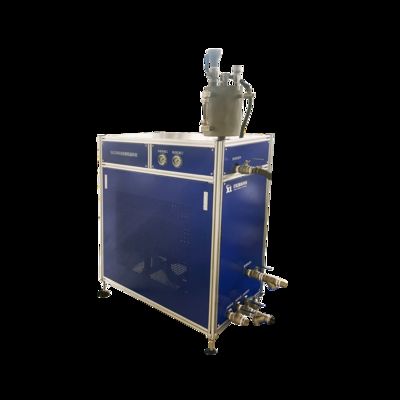

This solution uses the SLE-2120G lubricating oil station to provide constant pressure, constant flow, and constant temperature lubrication for the UUT. The device uses Siemens PLC as the main control unit, which can meet the lubricating oil supply under different setting conditions;

- Adjustable transmission bracket

The adjustable transmission bracket is connected to the transmission through a special connector to form a whole. The height of the transmission can be adjusted up and down by adjusting the lifting screw on the mounting bracket, thereby achieving three-dimensional adjustability of the transmission support; a special adapter tool is installed on the transmission bracket to fix the test piece.

The cast iron plate in this solution is a plane reference carrier made of high-strength cast iron HT250, which has the characteristics of reliable accuracy, stable use and convenient transportation.

The monitoring system is equipped with a high-definition night vision camera, a video recorder and an LCD display, which can monitor the product status in real time during product testing.

2. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Working Principle

The drive system outputs power to drive the gearbox according to the preset working conditions, the load system simulates the actual load, and the data acquisition system transmits parameters to the control system in real time, and the control system dynamically adjusts the drive and load accordingly. Video monitoring and sealing testing work together, and after the test, the transmission efficiency, load-bearing capacity and other indicators are calculated through data analysis to complete the performance evaluation.

3. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Usage Environment and Conditions

1). Power supply conditions: 380/220V AC 50Hz power supply, equipped with voltage stabilizer and UPS, voltage fluctuation within ±10%, frequency fluctuation within ±0.5Hz.

2). Working environment: Professional laboratory, ambient temperature -10°C~45°C , relative humidity ≤85% , with good ventilation, vibration isolation and sound insulation facilities.

4. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Electric Dynamometer Technical Parameters

SSCD600 - 1500 / 3500 Electric Dynamometer Technical Parameters

| Project |

Input end electric dynamometer parameters |

| Host model |

SSCD600-1500/3500 |

| brand |

Seelong |

| Rated power (KW) |

600 |

| Rated speed (rpm) |

1500 |

| Constant torque speed range (rpm) |

0-1500 |

| Constant power speed range (rpm) |

1500-3500 |

| Maximum speed (rpm) |

3500 |

| Overload capacity |

120% |

| Rated voltage (V) |

AC 380 |

| Rated torque (Nm) |

3820 |

| Cooling method |

Forced air cooling |

| Encoder |

Shanghai Jingfen |

| Encoder Type |

HTL 512 |

| Dynamometer safety monitoring |

Bearing temperature X2 |

| Coil temperature X3 |

| Vibration Monitoring X2 |

SSCD600 - 375 / 875 Electric Dynamometer Technical Parameters

| project |

Output end electric dynamometer parameters |

| Host model |

SSCD600 - 375 / 875 |

| brand |

Seelong |

| Rated power (KW) |

600 |

| Rated speed (rpm) |

375 |

| Constant torque speed range (rpm) |

0-375 |

| Constant power speed range (rpm) |

375 - 875 |

| Maximum speed (rpm) |

875 |

| Overload capacity |

120% |

| Rated voltage (V) |

AC 380 |

| Rated torque (Nm) |

15279 |

| Cooling method |

Forced air cooling |

| Encoder |

Shanghai Jingfen |

| Encoder Type |

HTL 512 |

| Dynamometer safety monitoring |

Bearing temperature X2 |

| Coil temperature X3 |

| Vibration Monitoring X2 |

5. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Reference Standards

QC/T 568-2019 Technical requirements and bench test methods for automotive mechanical transmission assemblies

QC/T-291-2023 "Performance requirements and bench test methods for automotive mechanical transfer case assemblies"

6. 600kW One-to-One Forced air cooling Gearbox and Axle Performance Testing and Reliability Testing Bench Application Areas

1). Automotive industry: used for the research and development and testing of gearboxes such as transmissions, and to optimize power systems.

2). Wind power generation: Test the performance of the gearbox under complex working conditions to ensure stable operation of the equipment.

3). Shipbuilding: Evaluate the reliability and impact resistance of gearboxes in navigation conditions.

4). Industrial equipment: Optimize the gearbox design of machine tools and other equipment to improve transmission efficiency.

5) . Aerospace: Ensure that precision gearboxes operate reliably under extreme conditions.

7. Exhibition

From October 24th to October 26th,2024, the Russian International Testing and Control Exhibition was successfully held at the Moscow Klokus Interbational Convention Center. Testing Control is an international testing and control exhibition organized by the renowned Russian exhibition company MVK, which is held anually in Russia.

As the largest and most influential testing and control equipment exhibition in Russia. The exhibition is supported by the Ministry of Defense of the Russian Federation, the Ministry of Industry and Trade of the Russian Federation, the Defense Committee of the State Duma, the Federal Bureau of Technical Regulation and Metrology, and the State Economic Development Bureau. During the three-day exhibition, the exhibition received a total of 10,237 visitors.

Seelong Intelligent Technology (Luoyang) Co.,Ltd. participated in this exhibition and mainly displayed its best-selling products to Russian market, such as engine test benches and transmission test benches. As the only supplier of power system testing equipment in China, Seelong has become a highlight of this exhibition. Visitors from aviation, automobiles, agricultural machinery, power generation equipment and other related fields visited Seelong for communication.

Through this exhibition, Seelong brand awareness in Russia has been strengthened, and it has provided an efficient platform for close communication with Russian partners and customers.

Company Profile

Seelong Intelligent Technology (Luoyang) Co., Ltd. is a high-tech enterprise specializing in equipment measurement, control, design, manufacturing, and sales services for power engineering systems in various fields such as aerospace, automotive, and new energy; The company is located in the beautiful peony city of Luoyang.

Seelong specializes in the research and development, production, and service of testing equipment for new energy motors, hybrid power systems, engines, transmissions, and more. Our main products include electric dynamometers, measurement and control systems, DC power supplies, and working condition guarantee systems. Seelong has a complete sales and service system, adhering to the business philosophy of providing fine quality services for survival and keeping on renovation for development, and providing users with various types of power engineering measurement and control solutions in various fields.

Seelong's advanced design philosophy and rich industry experience give the company a technological Advantages ahead of competitors in the same industry, and the company's products can better meet the actual market demand. Seelong is brave in innovation. While valuing its own technological breakthroughs and development, it has established long-term and in-depth cooperative relationships with multiple domestic research institutions such as Tsinghua University and Shandong University. It has passed CE certification, ISO9001 quality system certification, AAA level enterprise certification, obtained more than ten invention patents, and two software copyrights. It has provided professional equipment and services to more than a hundred users both domestically and internationally, The enterprise has won the trust of domestic and foreign customers with its cost-effective products and high-quality services, and has established a long-term win-win strategic partnership.

The company always adheres to the business philosophy of "taking technological innovation as its mission and quality service as its purpose", constantly surpassing the advanced level in the same industry, integrating into the world, measuring and controlling the future, and creating high-quality products. To provide customers with products and services with high intelligence, precision, speed, reliability, and added value.

All employees of Seelong Intelligent Technology (Luoyang) Co., Ltd. warmly welcome sincere cooperation from domestic and foreign customers, and work together for the future and common development.

Company Certificates

Packaging and Shipping

FAQ

Q: What's the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q:How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What's your payment term?

A: Normally 40% T/T deposit, pay in full before shipment.

Q:What's the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors production cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q: Can I come to visit your factory?

A: Sure, you are always welcomed to have a visit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!