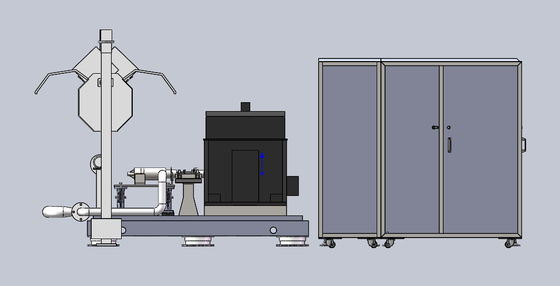

SSCD30 30KW 191Nm 5000rpm Electrical Test Bench For Diesel Engine And Gearbox

Introduction

The motor performance test system consists of dynamometer, dynamometer controller, electrical parameter measurement, test power supply, vertical console and electrical cabinet, dynamometer stand, fixture, computer and special test software, which can be changed arbitrarily The load of the motor under test can directly measure the input voltage, current, power and output torque, speed, output power and efficiency of the motor and the input voltage, current, power and efficiency of the controller under no-load, load and locked rotor states.

Main features of the system

1. The sampling time can be set

2. Setting of range and number of teeth: the user can set the number of teeth according to the corresponding torque range of the dynamometer and the number of teeth of the gear plate or photoelectric polarizer

3. Hub function: When multiple (≥2) dynamometers are configured, the hub automatically switches the corresponding signals to avoid operation errors and operation safety caused by frequent plugging and unplugging of signal ports when the dynamometer station is replaced.

4. Automatic calibration and calibration function: In addition to retaining the manual calibration (including positive full scale, negative full scale, and zero adjustment) functions, the user can automatically realize the whole process of dynamometer calibration on the computer, the calibration process is clear, and the calibration data can be stored. On the computer, the calibration data table can be automatically generated and printed out.

5. Durability function: According to the requirements of the tested motor, the number of cycles, time of each period, load size (including no load, light load, rated load, overload, stall, stop, etc.) and forward/reverse durability can be set arbitrarily Working conditions, and automatically display the set durability curve and the actual running durability curve.

6. Sampling synchronization of input and output parameters of motor operation: input voltage, current, power, power factor, frequency and output torque, speed, input power, efficiency. It has synchronous sampling during measurement to ensure data consistency.

7. The system has a complete self-inspection function, which is especially suitable for customers to quickly diagnose on-site and perform rapid maintenance.

8. Out-of-step point test and maximum torque point capture function: Many motors require automatic test of out-of-step point parameters or maximum torque point test in sequence at different speeds, and automatically generate out-of-step torque or maximum torque to speed (frequency ) characteristic curve.

9. Dynamometer load mode: excitation mode, constant torque mode, constant speed mode, constant current mode; PID function ensures fast dynamic response of load operation and more stable operation.

10. System accuracy consistency and repeatability: The repeatability of the dynamometer system accuracy is the most important indicator to measure the accuracy of the entire system. Without repeatability, the accuracy is meaningless.

Examples for Possible Applications

- Steady-state engine testing

- Engine mapping

- Power measurement

- Durability testing

- Component testing

- Application tests for injection systems and ECU´s

- ECU calibration tests

- Rapid motion aging tests

Test items

- No-load test

- Loading test

- Temperature rise test

- Efficiency test

- Locked rotor test

- Over speed test

| Moder Order No. |

Rated Power P Rated kW |

Rated Torque M Rated Nm |

Constant Power Range n2 rpm |

Max Working Speed n max rpm |

Measurement Accuracy %FS |

Constant Torque Range n1 rpm |

| SSCD15-1000/4500 |

15 |

143 |

1000-4000 |

4500 |

0.05/0.2/0.5 |

0-1000 |

| SSCD45-1000/4000 |

45 |

430 |

1000-3800 |

4000 |

0.05/0.2/0.5 |

0-1000 |

| SSCD60-1000/4000 |

60 |

573 |

1000-3800 |

4000 |

0.05/0.2/0.5 |

0-1000 |

| SSCD90-1000/3500 |

90 |

859 |

1000-3000 |

3500 |

0.05/0.2/0.5 |

0-1000 |

| SSCD110-1000/3500 |

110 |

1050 |

1000-3000 |

3500 |

0.05/0.2/0.5 |

0-1000 |

Scientific Research & Longitudinal Projects

2D model

FAQ

Q:What’s the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q: How can I learn more about the products?

A: Please leave your email and we will send you your electronic sample book.

Q: What’s your payment term?

A: Normally 30% T/T deposit, pay in full before shipment.

Q:What’s the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors prodction cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with you about the detailed plan.

Q:Can I come to visit your factory?

A: Sure, you are always welcome to have a visit.

About Us

SeeLong Intelligent Technology (Luoyang Henan) Co., LTD., is a professional production of automotive power system test equipment high technology services enterprises. SeeLong is located in the Peony City(famous for peonies) -- Luoyang, which is also the ancient capital of 13 dynasties.

Why Choose Us

After years of development and accumulation, the company has become a well-known powertrain test equipment production enterprises. Specializing in engine test, transmission test, energy storage test, controls and electric motor test and other test equipment research, development and production service. The company has established long-term cooperation with tsinghua university, Shandong university and many other domestic scientific institutions. We have successfully passed the ISO9001 Quality System certification, obtained a dozen of invention patents and two software copyrights. We have provided professional services and equipment for more than 100 users at home and abroad and which is ongoing now and will continue in the future.

Prospect of Cooperation

Friendly cooperation provides you both high quality products and long-term professional after-sales service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!